The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Table of ContentsGetting My Premier Aluminum Llc To WorkThe Greatest Guide To Premier Aluminum LlcPremier Aluminum Llc for Dummies3 Easy Facts About Premier Aluminum Llc Described

(http://www.place123.net/place/premier-aluminum-llc-racine-united-states)Traditionally, a buyer's key responsibility was to locate qualified and responsive suppliers. In many cases, buyers presumed that any provider willing to contractually meet the acquisition demand was qualified. However, making use of inexpensive and unqualified vendors can trigger high quality problems, and lost time and money over time. To aid you with the process, right here are some things to consider when picking the best metal spreading supplier.

As an example, a business that only makes use of the investment spreading process will certainly try to offer you on why that process is best for your application. What if using the sand spreading procedure is best for you and your needs? Instead, look for a supplier that supplies a range of casting procedures so the very best choice for YOU is chosen

If functioning with a solitary resource for all of your spreading requires is very important to you, the distributor requires to be diverse in its capabilities. When combined with other integrated capabilities, this can aid simplify and compress the supply base. When picking the appropriate spreading distributor, careful consideration should be offered to top quality, solution, and price.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Purchasers progressively choose casting vendors that have machining abilities. If the spreading distributor finds a concern during machining, the trouble is resolved much faster with no dispute over whose mistake it is.

Issue or no, incorporated machining simplifies the supply chain and decreases dealing with time and shipping price before the item makes it to the client. What do you need from your spreading supplier? Are you searching for somebody to just provide a metal part to your front door or do you require more? As an example, if you do not have internal metallurgy experience, validate that the vendor can supply support in choosing the proper alloy based on your specific application - Foundry near me.

Some factories are minimal or specialized. Make sure the supplier can satisfy all your product or alloy requirements to remove the need for several distributors.

The 7-Minute Rule for Premier Aluminum Llc

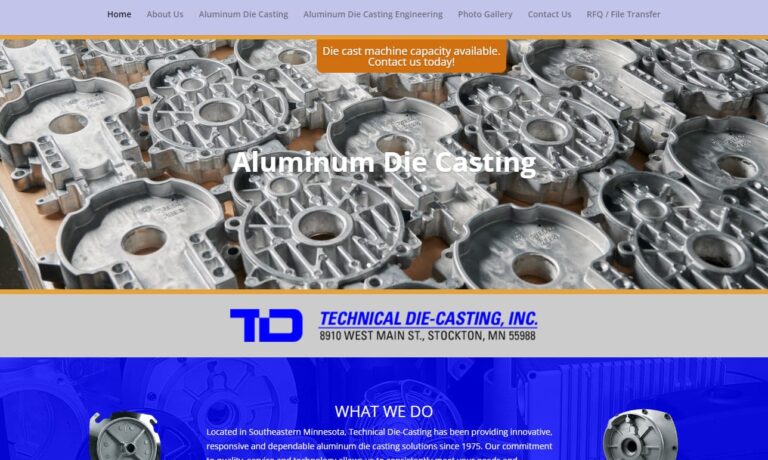

Study the distributor's internet site. Talk to a sales representative or service affiliate.

Light weight aluminum is additionally light-weight and has great corrosion resistance, making it optimal for applications where weight and longevity are very important aspects. Furthermore, aluminum spreading is an affordable method of production, as it needs much less power and resources than other techniques. Iron casting, on the other hand, involves putting liquified iron right into a mold and mildew to produce a wanted form.

The Main Principles Of Premier Aluminum Llc

Iron spreading is also able to endure heats, making it appropriate for use in applications such as engine components and commercial equipment. Iron spreading can be extra expensive than aluminum casting due to the greater price of raw materials and the energy needed to melt the iron. When deciding in between aluminum casting and iron casting, it is use this link necessary to consider the details requirements of the application.

In conclusion, both light weight aluminum spreading and iron spreading have their own distinct benefits and downsides. There are three sub-processes that drop under the category of die spreading: gravity die spreading (or irreversible mold spreading), low-pressure die spreading and high-pressure die casting. To obtain to the ended up product, there are three key alloys used as die casting material to choose from: zinc, light weight aluminum and magnesium.